Click on image for details

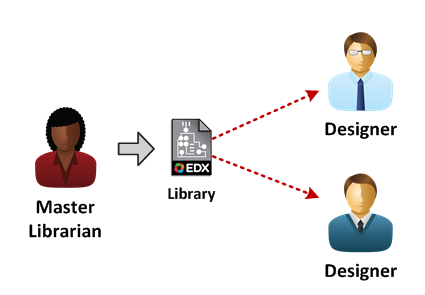

EDX can be used to keep remote libraries synchronized with the master. The master librarian can either initialize or update a remote library with the master, or send out updates when the library changes in response to new part requirements.

Click on image for details

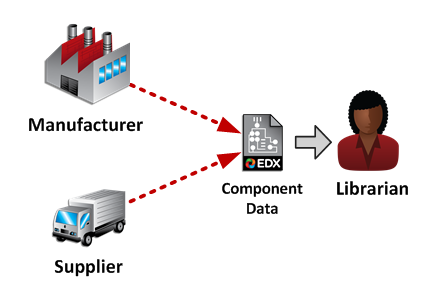

EDX can be used to integrate data from content providers into the library. Providing quality data to the designer leads to improvements in part selection in the early stages of the design process. EDX uses the latest technology for digital certificates to ensure that the data received has not been tampered with since it left the manufacturer.

Click on image for details

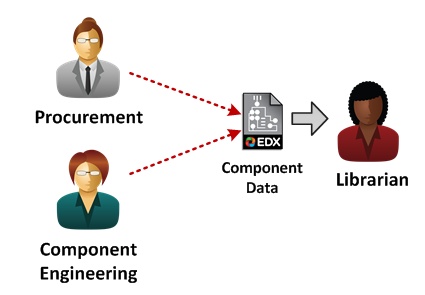

One of the use cases for an EDX integration is to complement the library with additional information that will ultimately help engineers in the selection of parts. The additional information can include supplier data such as online parts catalogs or company-specific manufacturer and supplier information. This is important because the additional information enriches the data that is available to the engineer to select the right parts for the design.

Click on image for details

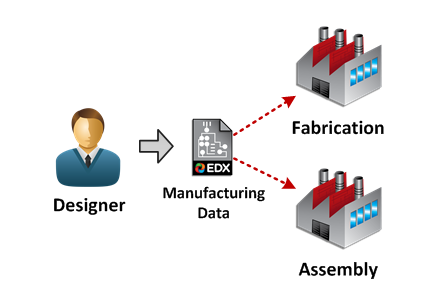

The release of a consistent data set for production is an important use case for EDX. The manufacturing and assembly release packages of EDX enable the release of an accurate data set that contains exactly the information needed for manufacturing and assembly.

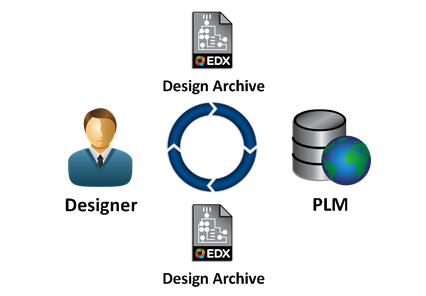

Click on image for details

EDX facilitates the archiving of a complete design container including all derived files and the product structure. The PLM system can archive the EDX package for later use as part of the change order process.

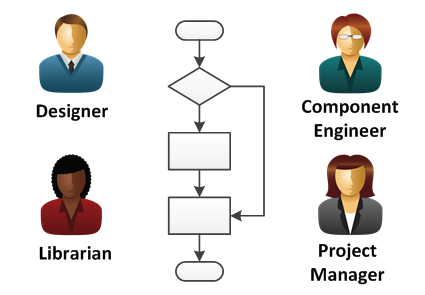

Click on image for details

EDX not only enables the exchange of library and design data, but also integrates change orders and introduction processes for new parts via work instructions. With the work instruction package it is possible to send a request between systems and thus trigger a process action. Each system can be the “owner” of a request for a new part or trigger the change request. EDX is flexible enough to recognize that either the authoring tool or external third parties initiate such requests.